System U

Resistance and safety guaranteed in any of our systems and nets.

- 1 piece antenna

- 2 pieces antenna

- Coated passivated carbon

- Cotton

- Cotton EN 1271

- Cotton with fringes EN 1270

- HDPE

- High Tenacity Polyamide

- Latex rubber on the inside coated with high tenacity polyester

- Nylon

- Nylon EN 1270

- Nylon EN 1271

- Nylon with fringes

- Nylon with fringes EN 1270

- PA

- PaHT

- PES

- PET

- PP

- PP (semi-circular goal)

- PP coated lead rope

- PPHT

- PPHT raffia

- PST

- PVC

-

Main product

Main product

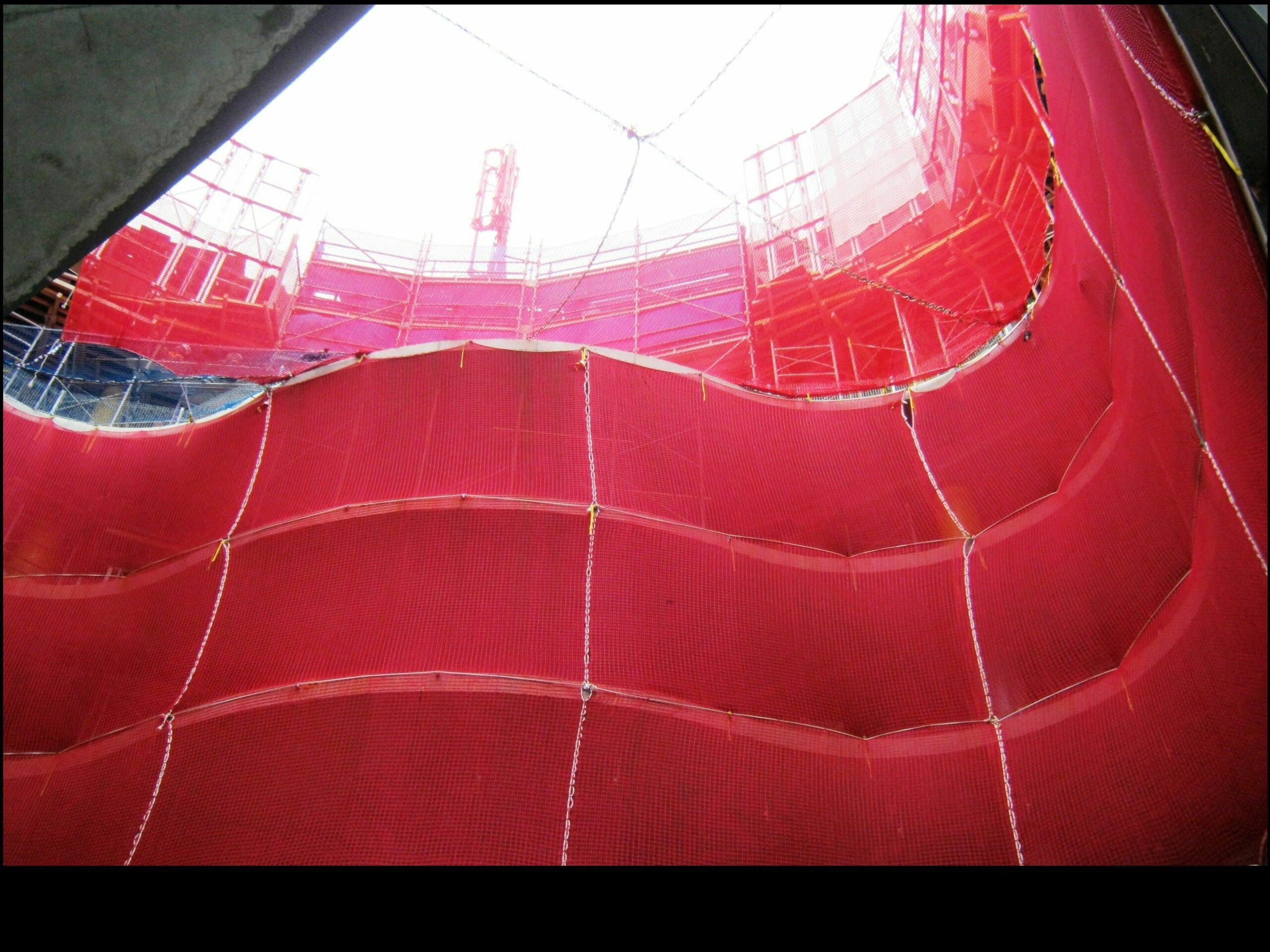

System U Net EN 1263-1

Safety net that acts as a guard rail.

-

Main product

Main product

Vertical locking

It covers the risk of a fall, preventing it from occurring.

-

Expanding metal anchor

It is used to hook and fasten the net into the slab. -

Strap

It is attaches the net to the guardrail tubes or safety guards. -

PVC cartridge

It is inserted into the concrete floor to support the steel railing that hold the balustrade -

Protective cap

It is used as a protection on corrugated steel rods. -

Binding rope EN 1263-1 7,5kN type O

Linking networks together.

Safety nets

We focus practically all our production on knotless polypropylene because it has the best qualities for compliance with European standards.

DIMENSIONAL STABILISATION OF THE KNOTS. Nets with knots need a thermofixing process to fix the knots. If this is not done correctly, it can lead to different mesh sizes within the same net, which is absolutely impossible for knotless nets.

KNOTLESS NETS TAKE UP LESS SPACE AND ARE EASIER TO PACK. Therefore, in terms of transporting the nets, this factor saves space and money.

KNOTLESS NETS ARE LIGHTER. This is also an important value when transporting and installing large nets.

DOES NOT CAUSE SERIOUS DAMAGE IN THE EVENT OF A FALL. In the event of a fall, people can suffer cuts, scratches and burns after contact with knotted nets. In the case of knotless nets this is unlikely as the surface of the net is flat.